- Home Page

- Company Profile

-

Our Products

- Duplex Board Grey Back

- HIGH BULK OFFSET PRINTING PAPER 180 TO 450 GSM

- PRINTED DUPLEX PAPER SHEET

- GOOD QUALITY DUPLEX BOARD

- GREY BACK DUPLEX BOARD (LWC) SUN PRIME

- Duplex Grey Back Board (Hwc)

- DUPLEX GREY BACK BOARD (LWC)

- Duplex Board - Roll

- Customized Size Duplex Board

- DUPLEX BOARD FOR PRINTING

- Duplex Board for Packaging

- Duplex Board

- Low GSM Duplex Paper

- ONP PULP

- 180-450 GSM DUplex Board

- Mixed Pulp Paper Shetts

- 250-350 GSM Offset Printing Duplex Board Grey Back

- DUPLEX BOARD WITH STRONG STIFFNESS AND EXCELLENT FOLDING RESISTANCE

- ANY SIZE OF DUPLEX BOARD

- SHARP SLITTING AND TIGHT REWINDING PAPER ROLLS

- Grey Back Duplex Board

- Duplex Board

- White Duplex Paper Sheet

- HIGH BRIGHT LIGHT WEIGHT COATED PAPER

- CLAY COTED DUPLEX BOARD

- POLY COATED DUPLEX WHITE BACK

- COATED DUPLEX WHITE BACK

- High Quality Duplex Board

- FACTORY PRICE - DUPLEX BOARD WHITE BACK

- Food Grade - Duplex Board

- Premium Quality - Duplex Board

- Double Side Coated Duplex Board

- Duplex Board From India

- High GSM Duplex Board

- Waterproof Duplex Board

- High Quality Packaging Duplex Board

- Offset Printing Duplex Paper Board

- White Duplex Packaging Box

- High Quality White Duplex Box

- White Woodfree Duplex Board

- White Duplex Board For Food Packaging

- WELL COTED DUPLEX BOARD GREY / WHITE BACK

- DUPLEX BOARD WITH NATURAL WHITE SURFACE

- BREAKLESS PAPER REELS

- DUPLEX BOARD

- PAPER FOR WHITE BOX

- Duplex Board

- Kraft Paper

- Premium Quality Kraft Paper

- KRAFT PAPER BAG PAPER

- KRAFT TEST LINER

- Waterproof Kraft Paper

- KRAFT FLUTING PAPER

- Recycled Kraft Paper Roll

- INDENTED KRAFT PAPER FOR HEAVY DUTY PARTS PACKING

- Good Quality Kraft Paper

- 3PLY/5PLY CORRUGATED BOX

- High RCT Brown Kraft Paper

- LOW GSM HIGH STRENGTH RECYCLED CORRUGATED BOX MAKING MATERIAL

- GOLDEN COLOR KRAFT PAPER

- High Strength Fluting Kraft Paper

- Kraft Packaging Paper Box

- HIGH BF KRAFT PAPER

- LOW GSM KRAFT PAPER

- POLY COATED KRAFT PAPER

- PRINTED KRAFT PAPER ROLL

- Cardboard Paper Core Tube and Pipe

- High Quality Kraft Paper

- Top Quality Kraft Paper

- Top Quality Brown Kraft Paper

- Industrial Kraft Paper

- Brown Poly Coated Kraft Paper

- Kraft Paper Box

- Brown Kraft Paper

- Kraft Paper Roll

- Top Quality Kraft Paper Roll

- Eco Friendly Kraft Paper Box

- Recyclable Brown Kraft Paper

- Industrial Brown Kraft Paper

- Export Quality Brown Kraft Paper

- Recycled Brown Kraft Paper

- Food Grade Recycled Kraft Paper

- Brown Kraft Paper Bag

- High Quality Kraft Liner

- WOODFREE KRAFT PAPER

- STANDARD QUALITY KRAFT PAPER

- WAXED KRAFT PAPER FOR FOOD PACKING

- ENVIRNMENT FRIENDLY BROWN KRAFT PAPER FOR PACKAGING

- KRAFT PAPER

- PAPER CORE PIPE

- MOISTURE PROOF RECYCLED KRFAT PAPER

- Kraft Paper

- Paper Pulp

- Paper Core & Pater Tube

- Angle Board

- Recycled Kraft Paper Tube

- Mini diameter Kraft paper tube / paper core

- Brown Krfat Paper tube

- CUSTOM SIZE PAPER TUBE AT FACTORY PRICE

- Unpainted Kraft paper core

- Kraft Paper Tube With Customized Color And Size

- Paper Angle Board

- High Quality Edge Protector

- Corrugated Paper Tube

- Corner Angle Board

- Best Quality Corner Protector

- High Grade Paper Core Pipe

- Yarn Paper Tube

- DTY Paper Tube

- Cardboard Angle Board

- Angle Board

- L shape brown paper Angle Board

- Kraft paper corner protector edge angle board

- Sharp Corner Protectors Angle Protector

- Industrial Cardboard Tubes

- Kraft Paper Core Industrial Cardboard Tube

- Various Sizes of Brown Kraft Paper Tube Textile Paper Roll Core

- Custom Printed Paper Tube

- 152mm Paper Cardboard Tubes

- Spiral Paper Tube

- Pallet Edge Protector

- Paper Core Pipe For Industrial Use

- PAPER CORE PIPE WITH THREE INCH DIA

- Wholesale Kraft Paper Core Industries

- Eco Friendly Paper Tubes

- WHITE PAPER TUBE

- Paper Core for Adhesive Tapes

- Corrugated Industrial Paper Tubes And Cores Pipe

- Printed Paper Tube

- Moistureproof paper tube of corrugated paper

- Core Pipe with Six inch Inner Dia

- HIGH CS PAPER CORE PIPE

- Round Cardboard Paper Tube

- 3 to 30 mm Thickness Paper Tube

- BEST QUALITY PAPER CORE PIPE

- Edge Protector With 4 mm Thickness

- Eco-Friendly Paper Packaging Tube

- Wholesale Round Kraft Paper Tube Roll Core

- Core Pipe

- Durable Paper Core Pipe

- Edge Protector For Paper Reel

- Edge Protector For Pallet Packing

- Multicolour Yarn Paper Tube

- Open End Paper Tube

- POY Paper Tube

- Paper Angle Flat Board and Protector

- 3 mm to 30 mm Brown Cardboard Tube

- 4 mm Thickness Paper Angle Board

- High Quality Kraft Paper Core Tube

- Kraft Yarn Paper Tube

- Paper Tube and Paper Core

- Moisture Resistant Protective Paper Angle Board

- New Design Brown Lock Edge Board Protector

- Kraft Paper Angle Protector angle board paper corner protector

- Paper Cardboard Tubes

- Kraft Paper Tube

- 76 mm Inner Dia Kraft paper tube

- Paper Tube

- Industrial Paper Tube

- PP Woven Fabric

- PP (Polypropylene) Woven Sacks Bag

- PP Woven Bags For Seeds Packing

- PP Woven Shopping Bag

- PP Woven Bags

- Biaxially Oriented Polypropylene Bags (BOPP)

- Top Quality Polypropylene Sacks

- PP Woven Bags Raw Material

- White Woven Bags For Packaging with Storage Capacity: 5-50 Kg

- PP Polypropylene Woven Fabrics and Sacks

- PP Woven Tubular Fabric Rolls and Tubular Bag Rolls

- 20kg,25kg,50kg Brown/White Laminated PP Woven Fabric Bag

- Polypropylene PP Woven Fabric Sack Roll

- High Quality Polypropylene PP Woven Laminated Bag

- Polypropylene Woven Fabric

- PP (Polypropylene) Woven Sacks Bag

- PP (Polypropylene) Woven Sacks Roll

- PP (Polypropylene) Woven Sacks Bags

- Wholesale Polypropylene woven bag sack rolls

- 50 Kg PP Woven Packaging Bag

- 50kg PP Woven Onion sacks

- Agriculture 50kg 20kg PP Woven Sack fabric

- PP Wrapping Fabric of Low GSM

- Jumbo Bag Polypropylene Fabric

- PP Woven Fabrics

- Waterproof Polypropylene Fabric

- PP Woven Fabrics For Wrapping

- PP Woven Fabric

- Customized Print PP Woven Bags

- Hot Selling pop cement 50kg bag from India

- Export Quality 20 kg and 50 kg PP Woven Bag

- 50 KG Rice Flour Packaging PP Woven Bags

- 50kg PP Woven Potato Sack

- PP Wrapping Fabric Low GSM

- Duplex Board Grey Back

- Export Market

- Contact Us

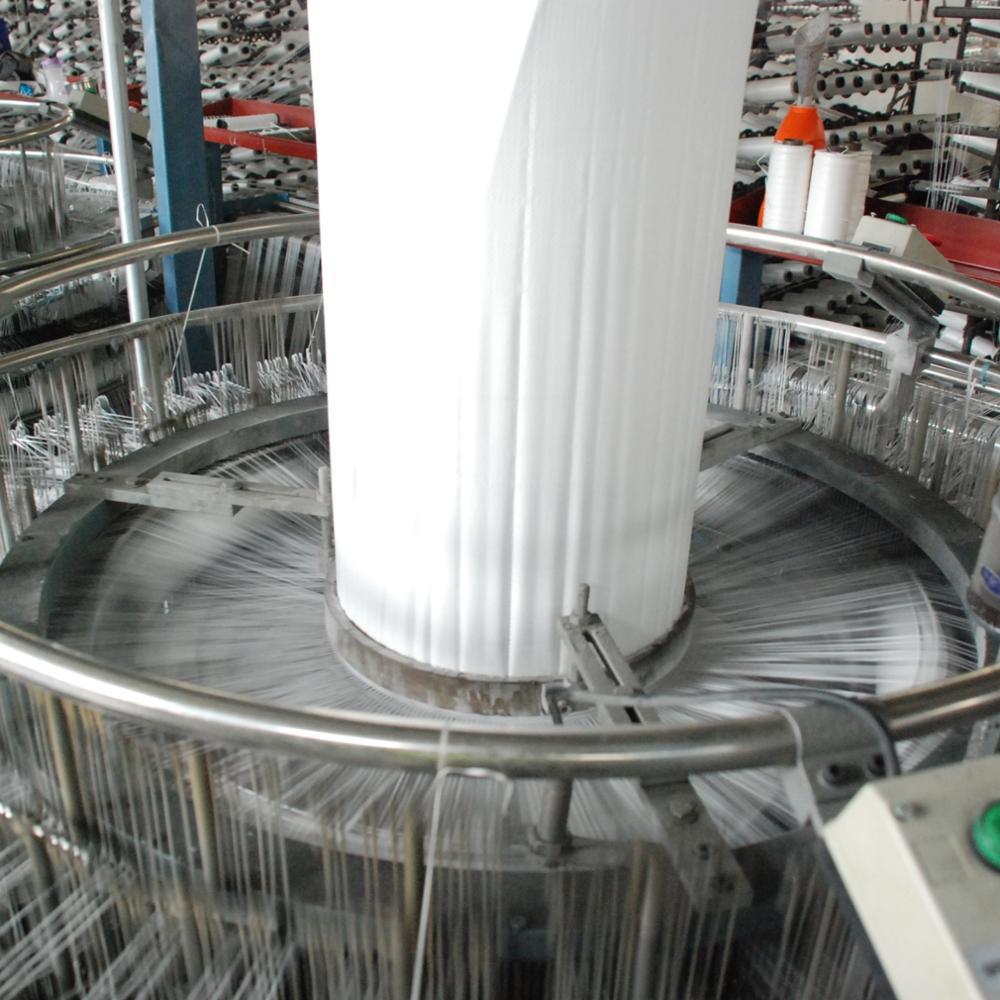

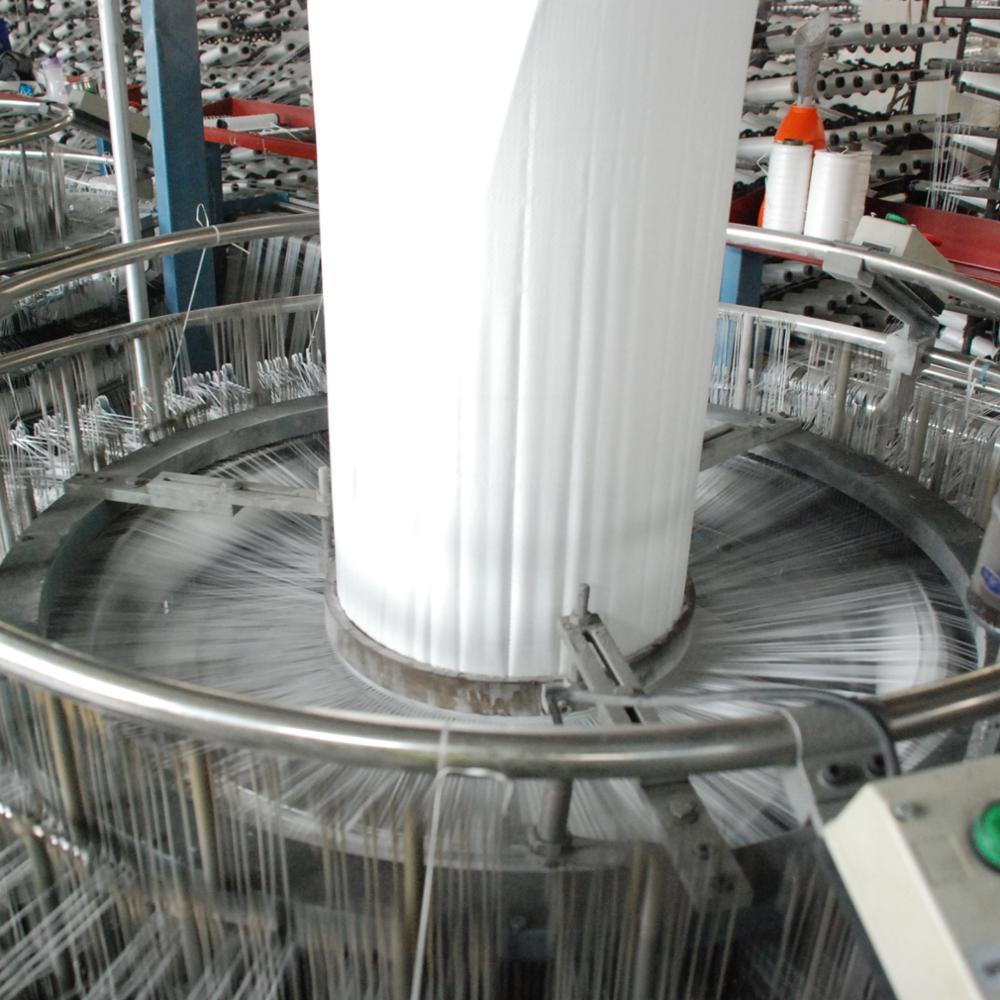

Jumbo Bag Polypropylene Fabric

MOQ : 20 Tons

Jumbo Bag Polypropylene Fabric Specification

- Feature

- Light in Weight, Flame Retardant, Waterproof, Anti-Static, Tear-Resistant, Shrink-Resistant, Anti-aging, Blackout, Anti-Pull, Heat-Insulation, Smooth, Light Texture, Washable, Anti-Wrinkle, Quick Dry, Fast Colors, Warm, Cool, Oil Proof, Sun-resistant, Stain Resistant

- Color

- as per requirnment

- Length

- as per requirnment Centimeter (cm)

- Fabric Type

- pp woven

- Yarn Type

- polypropylene

- Width

- as per requirnment Centimeter (cm)

- Material

- Other

- Texture

- Woven

- Pattern

- Other

- Technics

- Woven

Jumbo Bag Polypropylene Fabric Trade Information

- Minimum Order Quantity

- 20 Tons

- FOB Port

- MUNDRA

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 300 Tons Per Day

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About Jumbo Bag Polypropylene Fabric

These ranges of bags are manufactured with superior quality Biaxially Oriented Polypropylene (BOPP) films. These bags have high tensile strength and impeccable physical properties like good dimensional stability, water proofing, transparency etc. The advent of BOPP Printed Bags has increased the Branding options for our clients to attract buyers. These bags are available at highly competitive prices and customization is done as per the requirement of the client.

Advantages of BOPP BAGS:

Superior strength over paper bags-high tensile strength

Unlike paper bags, BOPP bags don't break or bust, so lower overall costs

Weigh less than traditional paper bags, which reduces freight costs

Strong, puncture & tear resistant, which reduces shrinkage from broken paper bags

Moisture proof

100% recyclable

High Gloss & Matte Finish

Resistant to oil and grease

UV inhibitor

Excellent printing quality that cannot be scratched or rubbed off

Excellent for marketing purposes, especially in the competitive retail sector

Not affected by moisture and does not wrinkle or shrink with environmental changes

Superior Performance & Customization

Our PP woven Jumbo Bag Fabric stands out due to its multi-faceted featuresranging from lightness and waterproofing to heat insulation and anti-static properties. Whether you need blackout capability or resistance to stains and oil, the fabric can be produced in custom colors, widths, and lengths to fit unique packaging or industrial needs. We offer full flexibility, ensuring each order is tailored to precise customer specifications.

Manufacturing Excellence in India

Manufactured using advanced weaving techniques and premium polypropylene yarn, our fabric guarantees reliability and longevity. As a trusted exporter and supplier, we adhere to stringent quality control and industry standards. Our production facilities in India are equipped to handle both bulk and custom orders efficiently, assuring prompt delivery wherever you are located.

FAQs of Jumbo Bag Polypropylene Fabric:

Q: How is Jumbo Bag Polypropylene Fabric produced?

A: Jumbo Bag Polypropylene Fabric is created through a specialized weaving process using polypropylene yarn. This method ensures the fabric is both lightweight and extremely strong, with woven techniques enhancing durability and resistance to environmental stressors.Q: What makes this fabric suitable for industrial packaging?

A: Its combination of flame retardancy, tear and shrink resistance, waterproofing, and anti-static properties makes it ideal for industrial packaging. Additionally, its oil proof, sun-resistant, and anti-aging characteristics ensure safe storage and transport of various goods.Q: Where can this fabric be used?

A: This fabric is commonly used in industries such as agriculture, construction, and logistics for making jumbo bags, sacks, covers, and liners. Its versatility also extends to areas requiring blackout, heat-insulation, or high levels of protection for stored goods.Q: What customization options are available?

A: We offer customization in terms of color, width, length, and pattern, enabling clients to specify exactly what is needed for their application. Both the shade and size can be tailored as per your project or packaging demands.Q: What is the benefit of using woven polypropylene for jumbo bags?

A: Woven polypropylene imparts excellent resistance to tearing, pulling, and weather effects while maintaining a light texture. This balance of strength and weight improves handling efficiency and cost-effectiveness in packaging and transport processes.Q: How does the anti-static and waterproof feature work?

A: The anti-static property prevents accumulation of static electricity on the fabric, enhancing safety in handling. The waterproof feature is achieved by the tight weave and special treatment of the fabric, keeping contents dry and protected.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PP Woven Fabric Category

PP (Polypropylene) Woven Sacks Bag

Price Range 2300.00 - 2500.00 USD ($) / Ton

Minimum Order Quantity : 20 Tons

Fabric Type : pp woven

Length : as per requirnment Centimeter (cm)

Feature : Light in Weight, Flame Retardant, Smooth, Light Texture, Washable, Quick Dry, Fast Colors, Oil Proof, Waterproof, ShrinkResistant, TearResistant, AntiStatic, Other, Sunresistant

Technics : Woven

PP (Polypropylene) Woven Sacks Bags

Price Range 2300.00 - 2500.00 USD ($) / Ton

Minimum Order Quantity : 20 Tons

Fabric Type : pp woven

Length : as per requirnment Centimeter (cm)

Feature : Light in Weight, Flame Retardant, Waterproof, Sunresistant, Antiaging, Blackout, HeatInsulation, Smooth, Light Texture, Washable, AntiWrinkle, Quick Dry, Warm, Cool, ShrinkResistant, TearResistant, Fast Colors, AntiStatic, Other, Oil Proof, Stain Resistant, AntiPull

Technics : Woven

50kg PP Woven Onion sacks

Price Range 2350.00 - 2500.00 USD ($) / Ton

Minimum Order Quantity : 20 Tons

Fabric Type : pp woven

Length : as per requirnment Centimeter (cm)

Feature : Light in Weight, Flame Retardant, AntiStatic, TearResistant, Sunresistant, Blackout, HeatInsulation, Smooth, Light Texture, Washable, AntiWrinkle, Quick Dry, Warm, Stain Resistant, Waterproof, ShrinkResistant, Fast Colors, Other, Oil Proof, Antiaging, AntiPull

Technics : Woven

PP Woven Shopping Bag

Price Range 2350.00 - 2500.00 USD ($) / Ton

Minimum Order Quantity : 20 Tons

Fabric Type : pp woven

Length : as per requirnment Centimeter (cm)

Feature : Flame Retardant, Waterproof, AntiStatic, TearResistant, Sunresistant, Antiaging, Blackout, HeatInsulation, Smooth, Light Texture, Light in Weight, Washable, AntiWrinkle, Quick Dry, Warm, Cool, Stain Resistant, Oil Proof, Other, ShrinkResistant, Fast Colors, AntiPull

Technics : Woven

|

DIYAN PAPERS LLP

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry